Capillary Tube Sizing Chart - Pressure (liquid and vapor) density (liquid and vapor) viscosity (liquid and vapor). This calculator uses the wolf and pate 2002 correlation. The two diagrams are used as follows: Then, for a given geometry, the flow rate correction is obtained from figure 3. The size of the cap tube is fairly critical. Unlike orifices, such as expansion valve seats, capillary tubes depend on their length as well as their. Locate recommended cap tube id in left hand column. The following capillary tube selections listed in table 1 and the correction factors listed in table 2 assume a 120°f. Capillary tube length and id. Read across and find conversion factor under copper cap tube size.

Capillary Tube Selection Table

Locate recommended cap tube id in left hand column. This calculator uses the wolf and pate 2002 correlation. Then, for a given geometry, the flow rate correction is obtained from figure 3. For given inlet pressure and subcooling level/vapour quality, the mass flow rate for the reference capillary tube can be estimated from figure 2; The following capillary tube selections.

Capillary Tubing Sizes Refrigerator Electromechanical Engineering

Unlike orifices, such as expansion valve seats, capillary tubes depend on their length as well as their. For given inlet pressure and subcooling level/vapour quality, the mass flow rate for the reference capillary tube can be estimated from figure 2; The size of the cap tube is fairly critical. Capillary tube length and id. This calculator uses the wolf and.

Supco Capillary Tube Chart

Reference chart for bullet® restricto capillary tubing for all refrigerants in low, medium and high applications. Locate recommended cap tube id in left hand column. Then, for a given geometry, the flow rate correction is obtained from figure 3. This calculator uses the wolf and pate 2002 correlation. Read across and find conversion factor under copper cap tube size.

Capillary Tube Sizing Chart

Capillary tube length and id. Locate recommended cap tube id in left hand column. This calculator uses the wolf and pate 2002 correlation. The two diagrams are used as follows: For given inlet pressure and subcooling level/vapour quality, the mass flow rate for the reference capillary tube can be estimated from figure 2;

Capillary Tube Conversion Chart Capillary Building Engineering

Then, for a given geometry, the flow rate correction is obtained from figure 3. For given inlet pressure and subcooling level/vapour quality, the mass flow rate for the reference capillary tube can be estimated from figure 2; The two diagrams are used as follows: The following capillary tube selections listed in table 1 and the correction factors listed in table.

How to design a capillary tube the simplest and most reliable

The two diagrams are used as follows: This calculator uses the wolf and pate 2002 correlation. Reference chart for bullet® restricto capillary tubing for all refrigerants in low, medium and high applications. Unlike orifices, such as expansion valve seats, capillary tubes depend on their length as well as their. Read across and find conversion factor under copper cap tube size.

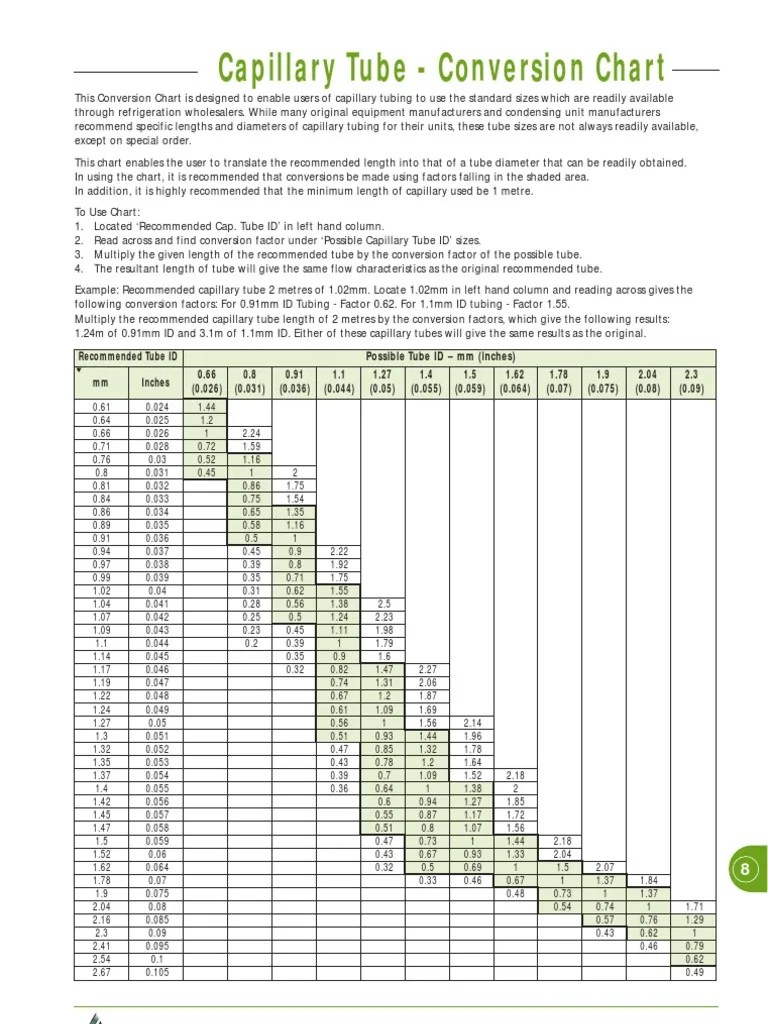

Capillary Tube Conversion Chart [PDF Document]

For given inlet pressure and subcooling level/vapour quality, the mass flow rate for the reference capillary tube can be estimated from figure 2; Locate recommended cap tube id in left hand column. Read across and find conversion factor under copper cap tube size. The following capillary tube selections listed in table 1 and the correction factors listed in table 2.

Capillary Tube Selection Chart

This calculator uses the wolf and pate 2002 correlation. For given inlet pressure and subcooling level/vapour quality, the mass flow rate for the reference capillary tube can be estimated from figure 2; Locate recommended cap tube id in left hand column. The size of the cap tube is fairly critical. Pressure (liquid and vapor) density (liquid and vapor) viscosity (liquid.

Cap Tube Sizing Chart

The size of the cap tube is fairly critical. Pressure (liquid and vapor) density (liquid and vapor) viscosity (liquid and vapor). Unlike orifices, such as expansion valve seats, capillary tubes depend on their length as well as their. This calculator uses the wolf and pate 2002 correlation. Locate recommended cap tube id in left hand column.

capillary tube conversion chart When a specific size tube … Flickr

Then, for a given geometry, the flow rate correction is obtained from figure 3. Locate recommended cap tube id in left hand column. Reference chart for bullet® restricto capillary tubing for all refrigerants in low, medium and high applications. The size of the cap tube is fairly critical. Read across and find conversion factor under copper cap tube size.

For given inlet pressure and subcooling level/vapour quality, the mass flow rate for the reference capillary tube can be estimated from figure 2; Unlike orifices, such as expansion valve seats, capillary tubes depend on their length as well as their. The two diagrams are used as follows: Then, for a given geometry, the flow rate correction is obtained from figure 3. Locate recommended cap tube id in left hand column. Capillary tube length and id. This calculator uses the wolf and pate 2002 correlation. The size of the cap tube is fairly critical. Reference chart for bullet® restricto capillary tubing for all refrigerants in low, medium and high applications. Pressure (liquid and vapor) density (liquid and vapor) viscosity (liquid and vapor). Read across and find conversion factor under copper cap tube size. The following capillary tube selections listed in table 1 and the correction factors listed in table 2 assume a 120°f.

The Size Of The Cap Tube Is Fairly Critical.

Read across and find conversion factor under copper cap tube size. Then, for a given geometry, the flow rate correction is obtained from figure 3. For given inlet pressure and subcooling level/vapour quality, the mass flow rate for the reference capillary tube can be estimated from figure 2; Pressure (liquid and vapor) density (liquid and vapor) viscosity (liquid and vapor).

The Two Diagrams Are Used As Follows:

This calculator uses the wolf and pate 2002 correlation. Locate recommended cap tube id in left hand column. Unlike orifices, such as expansion valve seats, capillary tubes depend on their length as well as their. Capillary tube length and id.

The Following Capillary Tube Selections Listed In Table 1 And The Correction Factors Listed In Table 2 Assume A 120°F.

Reference chart for bullet® restricto capillary tubing for all refrigerants in low, medium and high applications.

![Capillary Tube Conversion Chart [PDF Document]](https://i2.wp.com/cdn.vdocuments.mx/doc/1200x630/55cf9c6b550346d033a9c740/capillary-tube-conversion-chart.jpg?t=1660557794)